Lee ended up interning for Sustainable Down Source (SDS), which makes hydrophobic (water-repellant) goose down under the name DownTek, after bouncing ideas off her father, Albert Lee s*92, who was a visiting Ph.D. candidate at Princeton from 1988-90. She wanted a summer internship that would present her with a problem she could try to solve. After narrowing her options, she decided to try to find a way to make a better, more environmentally sound hydrophobic down, and she cold-called SDS.

They told her they’d never had an intern before, but they figured someone with scientific-trial experience could help them: They’d spent two years trying to come up with a high-performing, perfluorocarbon-free hydrophobic down, and so far had come up empty. Perfluourcarbons, more commonly called PFCs, are waterproofing chemicals that can cause health problems and do not biodegrade. SDS’s first attempt, ZeroPFC, wasn’t nearly as water repellant as its traditional formula, and they needed a better solution.

Lee dove in right away. She researched certified sustainable chemicals and emailed with a professor who had studied experiment design, to develop an efficient test. The chief sustainability officer for SDS had a long list of possible formulas. Lee narrowed them down and, within weeks, found the magic formula.

“No one at DownTek had ever thought to contact an academic,” Lee says, but it was that kind of thinking that ultimately prevailed.

The new DownTek isn’t just eco-friendly. A third-party rating showed the new formula can repel water for 25 hours, 50 percent longer than what DownTek’s original hydrophobic down. It appears to surpass performance of all other hydrophobic down products on the market, and DownTek has begun using this formula for the treated down it produces for companies like L.L.Bean, Big Agnes, Dynafit, and more. The new formula keeps PFCs out of hundreds of thousands of pounds of treated down each year.

Back at Princeton, Lee approached Eric Larson, senior research engineer at the Andlinger Center for Energy and the Environment, to advise her on a thesis analyzing the lifecycle of the product she helped create. She studied how down is acquired and transported, and visited SDS again to collect data and present her findings.

“Sam was proposing to take a practical problem and work on it in a scientifically rigorous way,” Larson says. She suggested ways for the company to reduce water usage by up to 96 percent — 106,000 gallons of water per month — through equipment upgrades. Lee also quantified the environmental impacts of down collection and transport.

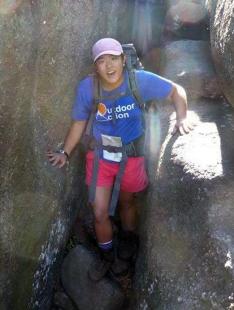

Lee now works as a new product engineer in the fabrics division of W. L. Gore and associates, which makes technical fabrics like Gore-Tex. She can’t say much about what she’s working on right now, but her Outdoor Action experience continues to impact the way she thinks. Her next goal? Helping to make the outdoors accessible to everyone by breaking down financial, social, and cultural barriers.

“The privilege of enjoying the outdoors shouldn’t just be reserved for the affluent, the ones who have vacation days to spare, car owners, or adrenaline junkies,” she says. “It can be as simple as taking a walk around the block, gardening, or watching a bug crawl along your windowsill. While I’m not quite sure exactly how to accomplish this [access] yet on a large scale, it is something I am very mindful of, whether I’m bringing an inexperienced friend on a hike or developing a new product in the lab.”