Professor Alan Blinder ’67 Offers an Alternative Economic Strategy for the 1990s

Alan S. Blinder ’67 is the Gordon S. Rentschler ’07 Memorial Professor of Economics. This essay is abridged from his book Growing Together, published in 1991 by Whittle Books, 333 Main Ave., Knoxville, TN 37902. Reprinted by permission.

In economic terms, the 1980s began on February 18, 1981, when the Reagan Administration’s fledgling economic team submitted a daring plan to Congress. Save for some details, we are still living the legacy of a strategy charted in America’s New Beginning: A Program for Economic Recovery. In the space of just twenty-six pages, this notable document diagnosed America’s economic ills (Jimmy Carter had done everything wrong), posted clear goals for the 1980s (including faster growth with lower inflation), and provided a road map for achieving them based on less government and lower taxes.

The most important success of Reaganomics was a prolonged expansion – lasting from early 1982 to mid-1990 – that reduced unemployment to 5.1 percent, a rate not seen since 1974. Inflation also melted away, though most of the reasons had naught to do with Reaganomics. But what of economic growth, the central concern of this essay? The decade since 1981 has actually witnessed slower average growth than the allegedly stagnant era that ended in 1981. Reagan’s supply-side economics did score slight gains in investment and productivity. But it failed to boost national savings, which as a share of the gross national product actually fell, from 16.8 percent to 13.7 percent.

Higher investment and declining savings meant more firms scrambling for fewer funds, a situation that pushed up interest rates to levels not seen in this country in half a century. And because Americans were saving less, we looked overseas to finance much of our investments. The United States became a giant financial vacuum cleaner, sucking in money from Japan, Germany, and other countries, and putting us in hock up to our ears. That, too, is part of the legacy of Reaganomics. Much of the unwanted inheritance of the 1980s can be summarized with what is fast becoming the four-letter word of the 1990s: debt.

The 1980s also witnessed a redistribution of income and wealth on a grand scale – far greater than in Lyndon Johnson’s Great Society, and perhaps comparable to Franklin Roosevelt’s New Deal. But there was a striking difference this time: the wealthy were on the receiving, not the giving, end. From the depths of the Great Depression until the 1970s, high and low income families grew more prosperous together, with the poor gaining slightly on the rich. Income gaps narrowed. Then everything changed as income growth slowed and inequalities began to widen.

In fairness to Reagan, the growing gap between rich and poor predated his Presidency, although the trend accelerated during his years in office. From 1973 to 1989, average family income advanced only about 1 percent a year in inflation-corrected dollars, versus nearly 3 percent a year from 1947 to 1973. But families near the top escaped most of the slowdown and continued to prosper. During the sixteen years ending in 1989, the real income of the average American family grew just 16 percent. The richest fifth, however, managed gains in real income of 26 percent, and the top 5 percent saw their incomes rise 34 percent. Meanwhile, the poorest fifth of families lost out not just relatively but absolutely, posting real income declines of almost 4 percent.

One cornerstone of Reaganomics was the use of tax incentives to spur capital formation, and hence economic growth. I’m certainly not against creating more capital: if Americans woke up tomorrow with a newfound desire to save and invest, I would lead the cheering. But such a policy assumes incorrectly that tax incentives that really work and don’t have negative side effects can be designed. The ideal incentive would subsidize all types of capital formation equally, boosting investment without inducing firms to buy, say, more computers and fewer blast furnaces. But in reality, tax incentives distort the allocation of capital, often to the benefit of special interests. Senator George Mitchell sensed this in 1986, when tax reform appeared to be breathing its last in the Senate Finance Committee. After a day in which the committee had decided to bless dental equipment, musical instruments, and caskets with more generous depreciation allowances than office furniture, communication satellites, and nuclear power plants, he moaned, “Here are twenty politicians defining what assets are productive and what are not. At least in the Soviet Union they use economists for that.” He might have added, “In America we are supposed to use capitalists.”In brief, a bigger stock of capital is not necessarily a better stock of capital. If tax breaks raise the quantity of investment, but decrease its quality, there is no guarantee that industrial productivity will improve.

In seeking a better way to achieve sustained economic growth, I suggest two guiding principles. The first is efficiency: more is better than less, so waste should be proscribed. The second is equity: because the poor are needier than the rich, some social redistribution toward the poor is appropriate. These two principles were joined metaphorically in the title of a book I wrote a few years ago: Hard Heads, Soft Hearts.

The hardheaded, softhearted approach leads to a concrete system of economic scorekeeping. Ask two questions. First, is a proposed policy likely to enhance or harm economic efficiency? If the latter, count a strike against it. Second, does the policy redistribute income in favor of the poor or the rich? If the latter, count another strike. In this game, two strikes mean you’re out: in a democracy, policies that make the economy less productive, while filling cups that are already brimming, ought to be rejected. But proposals that improve the prospects of society’s underdogs, while also enhancing economic efficiency, probably merit adoption.

It is over the difficult split decisions that political debate should take place. For example, suppose a cut in the top tax rate might make the economy more efficient. Is the efficiency gained worth the loss in social equity? The same sort of question arises with measures that sacrifice efficiency to benefit the poor; Medicaid and housing subsidies are familiar examples. In such cases, we must ask whether the equity gained justifies the efficiency lost.

Reaganites were correct to emphasize efficiency, and especially productivity, in their strategy for growth. But they were heartless to ignore the adverse distributional consequences of the policies they proposed. Is it fair to ask the poor to sacrifice for the rich? Similarly, 1960s-style romantic liberalism was right to value equality, but was foolishly inattentive to economic efficiency. No nation – no matter how rich – can afford such profligacy.

What we need in the 1990s is a growth strategy that is at once hardheaded and softhearted – a policy package that gets results, but not at the expense of the poor and near-poor. An economic policymaker should have the heart of a social worker but look at the world through green eye-shades, not rose-colored glasses.

When Lou Carnesecca, the basketball coach at St. John’s University, was once asked the secret of his successful teams, he had a ready answer: get good players. Carnesecca is a master of his craft, so his response may have been a trifle disingenuous. But his simple and correct point was that good things are likely to happen to a team whose players can shoot the lights out. So it is with a country’s work force. Good capital and creative management work better when combined with a labor force that is world class.

To improve the quality of America’s labor pool, I would begin at the bottom of the economic ladder, with the people of the so-called underclass, whom the Reagan Revolution left behind. The case for a bottom-up labor policy is based on both social justice and hard economics, for the United States puts itself at a crippling disadvantage by writing off the lowest 20 percent of its potential work force. Neither Japan nor Europe do that. In his keynote address at the 1988 Republican National Convention, Thomas Kean ’57, then the governor of New Jersey, got it right when he said, “There are no spare Americans.” Moreover, our population of young people (ages sixteen to twenty-four) has declined 15 percent in the last decade and will remain low for the balance of the century, when America will have to fill millions of entry-level jobs – from hamburger-flippers to medical interns – from the thin ranks of the “birth-dearth generation.”

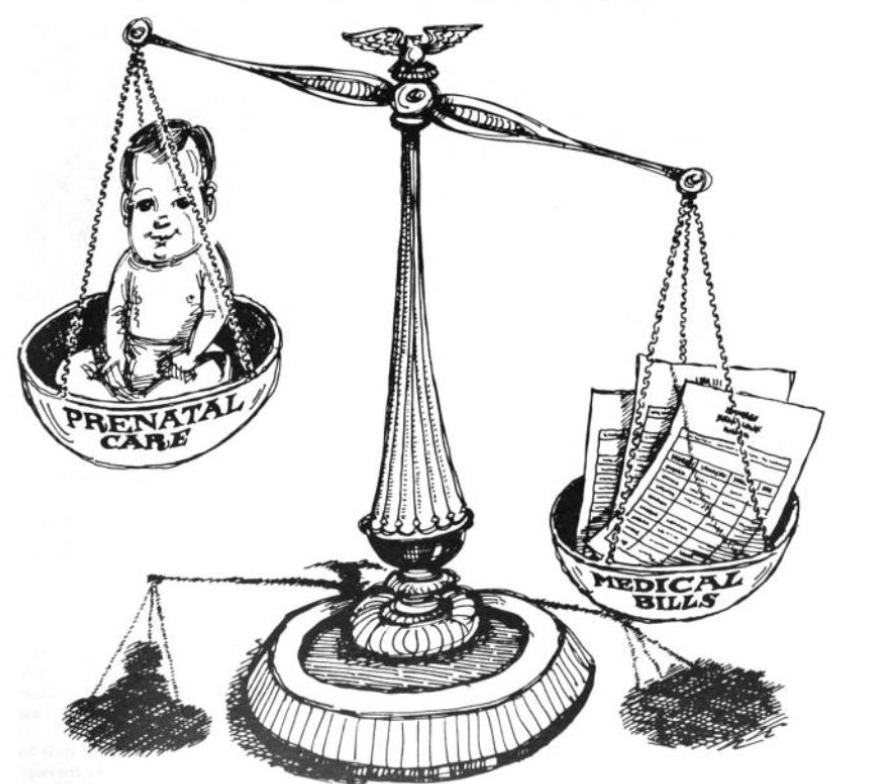

In 1987, the Committee for Economic Development, a blue-ribbon business organization, published a report on how to help the educationally disadvantaged. Titled Children in Need, this slender but fact-filled volume made an eloquent and persuasive case for a disarmingly simple principle: if you really want to have an impact on the cycle of poverty, focus your energies on children, especially on very young children.The government can accomplish much more if it intervenes early in life – with prenatal and post-natal nutrition and medical care, with counseling for young and expectant mothers, and with pre-school education. Numerous studies show that the investment in social programs for infants and children pays for itself many times over. The Colorado Health Department, for example, found that only 5 percent of women who had received early and continuous prenatal care gave birth to premature babies, as compared to 28 percent of women without such care. It estimated that each dollar spent on prenatal care could save nine dollars in medical expenses due to prematurity. A study in 1984 at the University of North Carolina estimated that every dollar spent on the Childhood Immunization Program saved ten dollars in subsequent medical costs. Such stunningly high returns would make a venture capitalist swoon.

Preschool education also pays handsome dividends. Project Head Start may be the greatest success story of the Great Society. It includes not only preschooling but also health, nutritional, and social services for needy children. Studies conducted over the first twenty-six years of its existence suggest that participating in Head Start increases I.Q. scores and perhaps the cognitive abilities of disadvantaged three and four year olds. Head Start children seem to perform better throughout their schooling: they attend more regularly, drop out less, and earn higher grades. Children who have gone through Head Start or similar programs also seem to enjoy more socioeconomic success in their teenage years and later. They are more likely to graduate from high school and attend college, less likely to commit crimes, become pregnant out of wedlock, or go on welfare. They appear to earn higher wages and experience less unemployment.

The most carefully designed and closely monitored experiment in preschool programs took place at the Perry Elementary School, in Ypsilanti, Michigan, near Detroit. Disadvantaged children who went through the program in the 1960s, along with a control group that did not, were tracked for twenty years, with social costs and benefits calculated in inflation-adjusted dollars. The findings are eye-opening. Because the program used such a low teacher-student ratio – one staff member for every five or six children – the costs were high: about $4,800 per student per year in 1981 dollars. But the benefits were vastly higher. For each student who spent a year in the program, the estimated benefit through the age of nineteen was more than $7,300 – mostly in the form of lower educational costs (the children needed fewer special services) and reduced crime (counting only the economic losses, not the fear or trauma experienced by victims).After the age of nineteen, the students’ gains mostly took the form of higher projected earnings and taxes paid, with some further contribution from lower crime rates. The authors of the study projected a subsequent gain in earnings of $23,800 over the lifetime of a typical child in the program, and another $3,300 of savings in lower welfare and crime costs. Thus, from an initial outlay of $4,800, the total social return topped $34,000. Quite an investment!

Beyond preschool, education is on everyone’s list of growth-enhancing policies – and should be. Even a cursory look around the world reveals an undeniable association between education and levels of income. Better-educated nations are richer. Certainly, a factor in the strong correlation between a nation’s average income and its average educational attainment is simply that education is a luxury wealthier countries can better afford. But that can’t be the whole story. Volumes of research attest that education – at least some forms of it – boosts productivity directly, especially in countries where the average educational attainment is low.

At least twenty million Americans over the age of eighteen are either functionally illiterate or just barely literate. How can the United States field a capable blue-collar labor force when such a substantial minority of its workers cannot read or write or do arithmetic? Executives of major American manufacturing companies bemoan the scarcity of literate blue-collar workers. Lester Thurow, an economist at M.I.T., points out that German and Japanese factories use “unlocked” machine tools that can be adjusted by workers when there is a simple malfunction, whereas American manufacturers use “locked” machine tools because our blue-collar workers cannot be taught the simple programming skills needed to adjust them. When equipment breaks, work ceases until the mechanic comes.

To reduce illiteracy, we will almost certainly have to spend more on compensatory and remedial education. We will probably have to raise teacher salaries and do other things (such as ensuring school safety) to improve both teaching and learning in inner-city schools. None of these will come cheap.

Whereas a campaign against illiteracy would offer the most help to those at the bottom of the economic pyramid, greater efforts in science and mathematics would do the most good at the top. No single fact can convey the nature of a complex problem, but the following comparison between us and the Japanese comes close. In the United States, the number of new lawyers and accountants each year roughly equals the number of new engineers. By contrast, Japan produces about one hundred engineers for every lawyer or accountant. Should we be surprised, then, that Japan leads the world in engineering while we lead the world in litigation?

America’s problems with science start early in the schools and continue right up to the top. International comparisons of mathematical and scientific achievement consistently place American schoolchildren well down on the list, while Japanese children always score near the top. The most recent rankings of achievement in science, for example, put American fourteen-year-olds thirteenth out of seventeen nations (tied with Thailand). At the collegiate level, Americans do much better, and at the graduate-school level, we are unrivaled; few if any foreign institutions can match schools like M.I.T., Cal Tech, Harvard, or Princeton. The problem is that too few American youths choose scientific careers. Our fine graduate programs in science and engineering are filled with foreign students, while American kids flock to law and business schools.

Americans have come to realize that the secret to Japan’s industrial success lies not in the way the Japanese manage capital, but in the way they manage people. A classic story, told by an American industrialist, makes this point. One of Nippon Electric Company’s semiconductor plants was generating an unusually large number of defective products, but no one could figure out why. One day, as the company’s engineers were pondering the problem, a young woman walking to work was stopped at a railroad crossing near the factory while a long freight train rumbled by. Like everyone who worked at the plant, she knew about the quality-control problem. Because she had been trained extensively and rotated through most positions on the factory floor, she was familiar enough with the technology of chip making to get an idea: perhaps vibrations from the trains were causing the problem. Later that day, she shared the thought with her foreman, who agreed it had merit. So did the plant manager, who decided to have a trench dug around the factory and filled with water to cushion the vibrations of passing trains. It worked. The rate of defects declined drastically. One then was N.E.C.’s headquarters, in Tokyo, informed of the solution.

After telling this story, the industrialist pondered what might have happened if the factory had been owned by a large, bureaucratic American corporation. First, the worker might never have been told of the dimensions of the defect problem. Second, even if she had, she probably wouldn’t have known enough about chip manufacturing to realize that vibrations could imperil the process. Third, even if she’d had the idea, she might have thought, “That’s management’s problem, not mine.” And fourth, even had she pushed ahead with her proposal, her foreman might have resisted. With apathetic fellow workers, indifferent superiors, and no quality circle or access to management, the alert worker might have found it impossible to get a hearing.

No one really opposes cooperation between labor and management. The real question is, What concrete steps can workers and executives take to turn factories, offices, and shops into more cooperative environments for work? I suggest two: profit sharing and employee involvement.

In the early 1980s, the economic theorist Martin Weitzman suggested that if workers received part of their compensation in the form of shared profits, rather than in straight wages, firms would be less inclined to lay them off when business conditions worsened. Because slumps cut profits, they would automatically reduce profit-sharing payments to employees, thereby paring the cost of labor without the need for layoffs. The widespread use of profit sharing, Weitzman reasoned, might reduce unemployment, thus ridding capitalism of one of its least attractive features. Subsequently, a survey of studies of the effects of profit sharing suggested that the practice typically boosts productivity by from 3 to 11 percent.

Critics of profit sharing raise three main objections. First is the “free-rider problem.” It’s no mystery why self-employed people and small, privately owned firms typically use profits as motivators, while giant corporations do not. To an owner-manager, the link between effort and income is clear, but to an employee of a company with, say, ten thousand workers, the corresponding connection is, at best, dim. Joe Sixpack’s hard work might boost his company’s profits by $10,000, but if all employees are entitled to a 20 percent share of the profits, his prorated share will be just twenty cents. Some incentive! So if Joe prefers the easy life, he’s likely to look for free rides based on the efforts of others. Nothing will eliminate the free-rider problem. But companies can minimize it by instilling a spirit of community, a sense of belonging to something bigger.

The second problem with profit sharing is that workers may be loath to put part of their wages at risk, especially if they distrust management. But workers worried about the risks of sharing profits should understand that their jobs are not now risk-free assets. Under the conventional wage system, their main peril is the risk of being laid off. Under the profit-sharing system, layoffs would be comparatively rare, but the risk of wages dropping during a recession would be greater – a reasonable tradeoff, it seems to me.

Furthermore, a well-designed profit-sharing plan can limit a worker’s financial risk. Most plans in the United States grant employees shares in their companies, but immobilize those shares in their pension fund until the workers retire. This policy is a mistake, for it burdens workers with terribly undiversified portfolios. As an alternative, periodic cash payments tied to profits would reduce workers’ vulnerability if their companies later run into trouble.The third problem is that workers who are asked to bet part of their income on the company’s profits may feel entitled to a voice in how the company is run. Critics of profit sharing fret that any infringement on management’s authority will impair the efficiency of a capitalist enterprise. But I think the opposite case can be made. As a production worker in an auto-parts plant told Business Week, “Everybody that works here is competitive. We’re willing to work long hours. We want to be multiskilled and learn how we can make the product better so we can be the best in quality and service to the customer. And if we do that, this plant will be around a long time.”

You might assume that the speaker works for Toyota or Honda. In fact, this gung-ho employee is Robert Hubble, who works in Blacksburg, Virginia, at an automotive-filter plant of Corning, Inc.

Perhaps no American company has taken employee involvement further than Corning, which in the mid-1980s began making radical changes in response to foreign competition. According to Norman Garrity, the executive vice-president, management concluded that “if you don’t pay attention to the people aspects, such as empowering workers to make decisions, you could only get 50 percent of the potential benefit of restructuring.” So Corning started to pay attention.

When the Blacksburg plant opened, in 1989, it boasted not only the latest equipment but also a reduction in the number of job classifications, from forty-seven to four, allowing carefully selected workers to acquire new skills by rotating jobs. (In Marysville, Ohio, Honda has gone even further: there is just one blue-collar job category.) Work is organized into self-directing teams, eliminating several layers of management. The Blacksburg plant is run by just three managers. Results have exceeded the company’s expectations. Despite the exceptionally high cost of training its all-new work force, the plant turned a profit in its first year of operation. A production line can now be retooled to produce a different kind of filter in one-sixth the time it takes at a traditional plant. And the employees, despite putting rigorous twelve-and-a-half-hour work days (either three or four per week), are delighted. “We have a lot of responsibility,” says Hubble, “but that makes me feel good.”

This success story and others show that a minority of American businesses are already making excellent use of worker participation to raise productivity, cut costs, improve quality, and boost sales. Of twenty-nine recent studies of worker participation in American firms, fourteen detected either large or lasting improvements in productivity, two found negative effects, and thirteen showed productivity gains to be either small or short lived. Although such findings may be ambiguous, they make it easier to believe that, at the very least, participation helps rather than hurts productivity.

Abroad, of course, there is the example of Japan, where employee involvement in decision making is the norm. That Japanese management has made (almost) the same system work in its factories in the United States – with American workers – should make us take notice. Just what are the salient features of the Japanese system of industrial relations?

• Job Security. Lifetime employment is central to the Japanese way of doing business. Workers whose jobs are secure are not threatened by change. Like Robert Hubble, they welcome innovations that are good for the company. That’s precisely why the Japan Productivity Center made job security one of its three guiding principles when it began its productivity-enhancement campaign, in 1955.

• Training. Japanese firms invest much more in training their workers, spending about double what American companies typically do (between 1 and 2 percent of payroll). When Japanese companies come here, they bring this strategy with them. An M.I.T. study of the automobile industry found that Japanese auto plants in North America give their workers about eight times as much training as the American plants.

• Job Rotation and Flexibility. Extensive training and job rotation give Japanese firms work forces that are not only highly skilled but also extremely flexible, making it easier for the companies to respond to changes in demand and technology – and to guarantee lifetime employment.

• Egalitarian Workplaces. Japanese executives pride themselves on having created a classless corporate community. The point is doubtless exaggerated; all that bowing surely signifies something. But comparisons between Japan and the United States are still striking. For example, the gap in salaries and benefits between top management and the rank and file is vastly larger in this country than in Japan. And Japanese firms rarely have special parking lots or dining rooms for executives. In Japan, young management trainees start out on the shop floor, learning the business from the ground up.

• Teamwork and Participation. Japanese normally work in teams. Quality circles – an American invention – are extensive and successful. The Japan Productivity Center estimates that about 85 percent of all employees in Japan’s major manufacturing companies take part in quality circles and that the average worker makes twenty-two suggestions per year! From a geyser of ideas like this, a few good ones are bound to spew forth now and then.

• Pay Structures and Fringe Benefits. Studies comparing wage structures have concluded that, in Japan, wage differentials among various types of workers are smaller, but the financial reward for longevity in firms is much greater. No one should be surprised that such a system encourages workers to stay on the job longer.

All in all, the frequently drawn analogy between a Japanese firm and an extended family does not seem too farfetched. The key question, of course, is, Can these highly paternalistic labor practices be profitably integrated into a culture as individualistic as ours? The examples of Corning and the Japanese auto firms with successful factories in the United States suggest that many of them can. And we shouldn’t forget that leading American companies, like Hewlett-Packard, exported some of these very practices to Japan years ago, or that General Motors has used the lessons it learned from Toyota at their jointly owned plant in Fremont, California, to create its unconventional Saturn division.

I suspect that many Japanese labor practices would work very well in the typical American plant. After all, the desire for job security is hardly unique to the Japanese. And if workers did not fear for their jobs, why would American unions insist on the narrow job descriptions and restrictive work rules that make many factory jobs so deadening? Most American workers, I trust, would like management to consult them on how their workplaces should be organized. And wouldn’t more extensive profit sharing and lower pay for executives help align the interests of labor and management, thereby promoting industrial cooperation? Such changes in industrial relations require neither legislation nor huge expenditures of capital. They require only that managers go out and put them into practice.

The good news is this: if human resources are indeed the “secret” to Japan’s industrial success, it is no secret at all. America can educate and train its workers better. We can treat them better on the job and listen to their suggestions. Our companies can share more of the fruits of their success with their employees. And if we do these things, America’s human resources can become the positive engine for growth that they once were. American industry can, I believe, gain more by adapting and adopting a few Japanese human-resource practices than by wringing a thousand trade concessions out of the unwilling Japanese.

This was originally published in the March 4, 1992 issue of PAW.

No responses yet