Alum's startup company bets on Princeton research

An enterprising alumnus has turned a Princeton materials-science innovation into a promising startup company. John Lettow ’95, president and co-founder of Maryland-based Vorbeck Materials, is applying research by professors Ilhan Aksay and Robert Prud’homme to create a novel form of graphite that could be used in inks and coating materials for electronic devices.

Lettow, a chemical engineer who earned his Ph.D. and M.B.A. after leaving Princeton, visited Aksay’s lab in 2005, 10 years after the professor advised his senior thesis. He was looking for an innovative idea to launch a new company, and Aksay provided the answer with the Princeton team’s groundbreaking work on graphene, a one-molecule-thick layer of graphite that has extraordinary properties.

Graphite, as most people know it, is quite brittle — think of the tip on a freshly sharpened pencil. But graphene sheets, the individual carbon-honeycomb layers that make up graphite, are remarkably strong. “In fact, there are some recent publications indicating that [graphene] is the strongest material ever measured,” Lettow said, “and ... the most thermally conductive material yet measured.”

Graphene also conducts electricity, and that quality, combined with its strength, has made it a hot topic in materials science. Chemical & Engineering News noted that more than 1,000 papers about graphene have been published since 2007. Researchers envision applications that range from computer circuits to car tires.

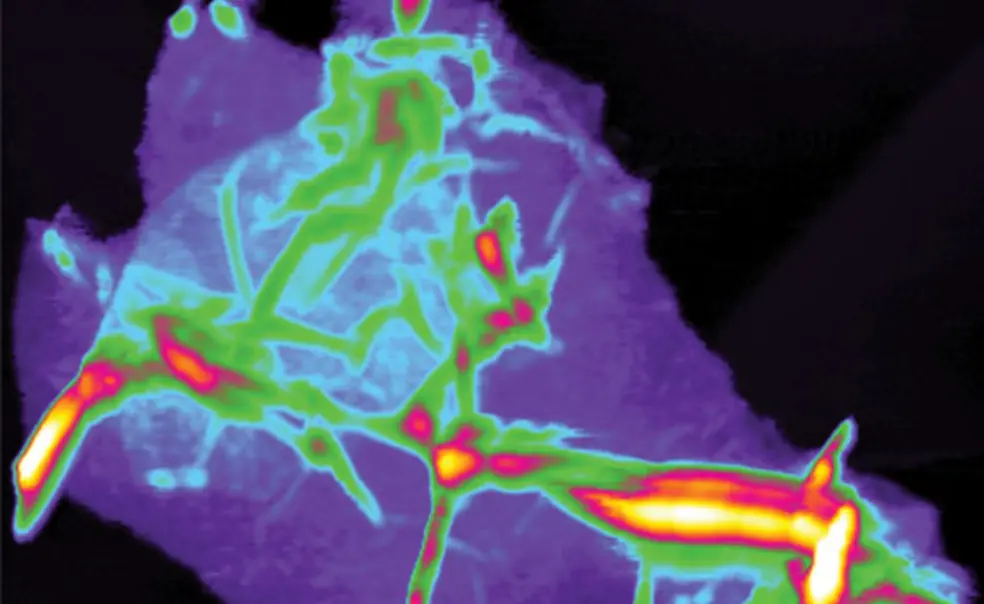

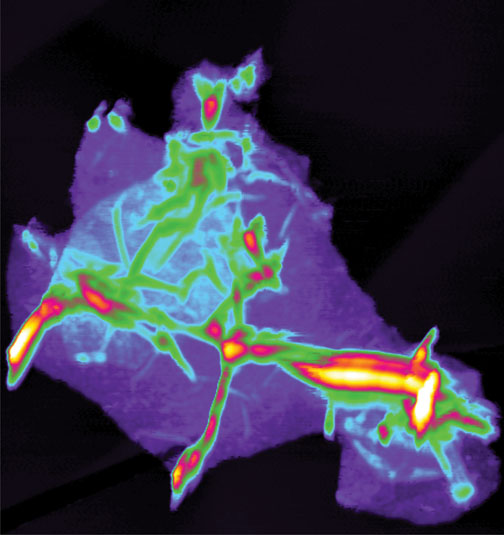

The challenge is peeling apart those ultrathin layers. Aksay’s team, together with Prud’homme, solved that riddle by devising a two-part process that weakens the bonds between graphene sheets and then pops them apart. Aksay explains the process using sheets of paper, held together with imaginary staples. If you want to separate the sheets, you first need to remove the staples. In the case of graphite, that is done by soaking the material in a strong acid for at least 72 hours.

Then, to lift the sheets apart, the Princeton method heats the material rapidly to a temperature above 1,000 degrees Celsius, creating a “popcorn” effect. The sheets crumple, each in a different pattern, keeping the graphene separated as single sheets.

A handful of companies have joined the rush to produce industrial quantities of graphene, but Lettow believes that Vorbeck has an edge, thanks to its exclusive license of the Princeton team’s patented process.

Licensing agreements are a small but important part of research at Princeton. Each year, the University completes five to 10 new agreements, according to John Ritter, director of the Office of Technology Licensing and Intellectual Property. (The number of patent disclosures is higher — usually between 80 and 100.) The licensing program aims to turn top research into applications that will provide a public benefit, Ritter said. Occasionally, a licensing deal also brings significant financial gain.

The most prominent case at Princeton is Alimta, an Eli Lilly cancer drug based on a compound developed by emeritus chemistry professor Edward C. Taylor. Lilly reported $1.15 billion in sales for Alimta last year; its fees accounted for a large majority of Princeton’s 2007–08 licensing income, which totaled about $50 million.

Vorbeck’s sales are a long way from that type of success, but the company made a significant step forward in December 2008 when it announced a joint research program with BASF, the world’s largest chemical company. The collaboration will focus primarily on compounds for the electronics industry, including graphene-based inks that could be used in printed electronics, which are an alternative to traditional etch-based circuits.

Aksay said that without Lettow, his lab might not have had an influence on commercial applications, but Lettow questions that notion. In both industry and the academy, he said, people have recognized the quality of Aksay’s work. Vorbeck simply provides a bridge, turning an exciting idea into a viable investment.

“The real role of the entrepreneur in this case is to take the risk,” Lettow said. “To go out and say, ‘We think it can be done,’ and then actually prove it.”

No responses yet