BREAKING GROUND: Nooks, crannies boost solar cells

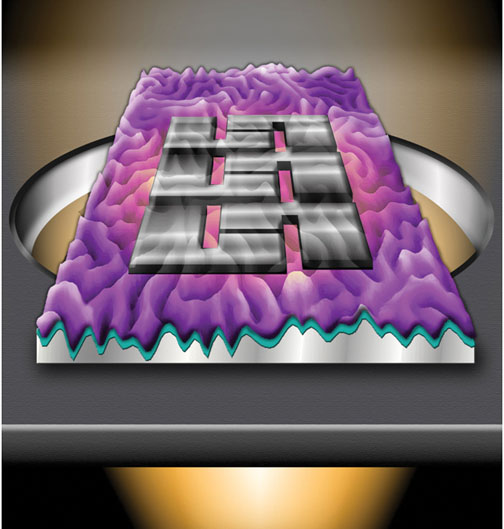

INSPIRED BY NATURE Wrinkles are not always bad, and folds are even better. By introducing microscopic wrinkles and folds to plastic surfaces and applying polymer solar cells on top, Yueh-Lin (Lynn) Loo, professor of chemical and biological engineering, and her colleagues have demonstrated a 47 percent increase in the efficiency of light absorption compared to a plastic solar cell on a flat surface. The nooks and crannies in the surface even extend absorption beyond the visible light spectrum and into the near-infrared spectrum.

The patterns of folds in the surface are similar to those found on leaves, the ultimate example of a miniature solar-energy powerhouse. “If you look carefully at leaves, the surfaces are not flat — there is a lot of structure,” said Loo. Scientists believe that the structure of leaves creates a more effective way to guide light to cells where photosynthesis takes place. “Photosynthesis itself is efficient, but you need to harness as much light as possible,” Loo explained. Her lab applied the same rationale to solar cells.

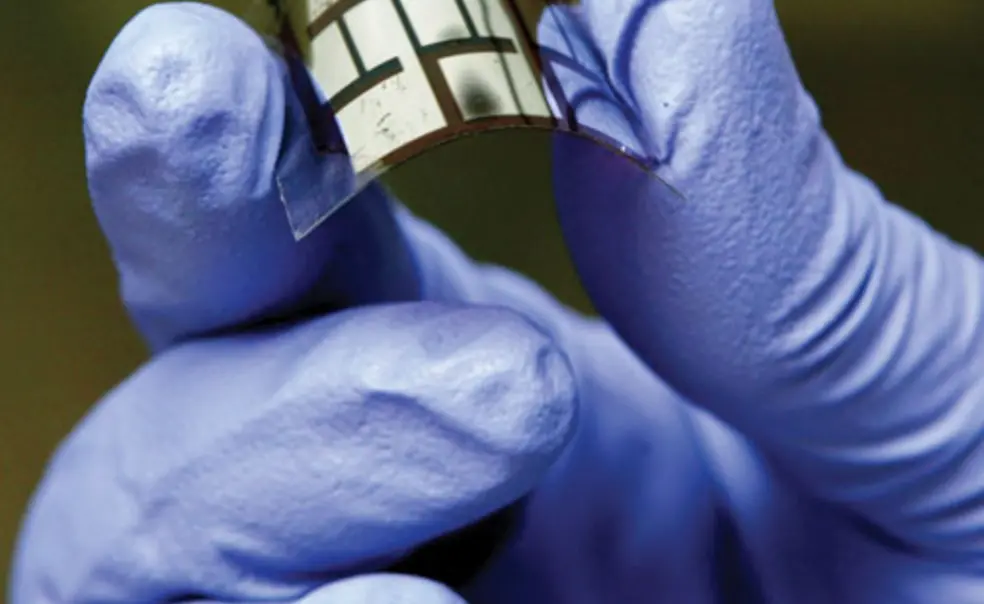

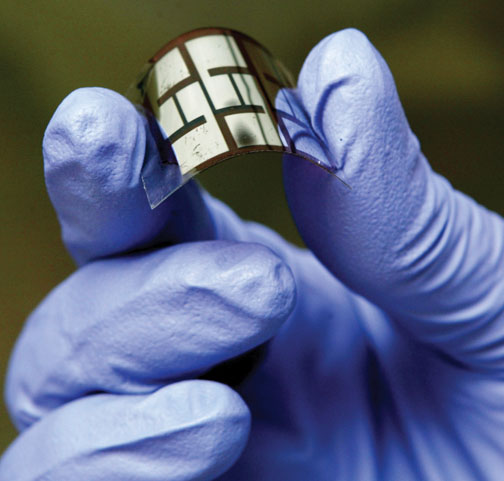

WHAT’S AHEAD Solar panels currently are made from silicon — a rigid, brittle material that requires an energy-intensive process to make. Loo’s research focuses on making solar panels from plastics, a lightweight material easy to manipulate and make at low cost. Solar panels can be printed on these surfaces using a process analogous to printing newspapers and magazines on paper.

“We think that [our approach] is a simple process that you can extend to large surfaces,” said Loo, deputy director of the Andlinger Center for Energy and the Environment. The ultimate goal is to translate the discoveries into techniques that manufacturers can incorporate into the design of better, more efficient solar cells.

HOW CAN WE USE IT? In the future, durable and flexible plastic solar panels could power your cellphone with small panels on your backpack, or let you charge your tablet computer on a camping trip via panels integrated on your tent. “The big goal is to have building-integrated [plastic] solar panels,” said Loo.

Loo and her team also are applying the wrinkled-surface approach to other plastic polymers that already absorb light in the near-infrared range. Low-cost, large-scale plastic solar panels may be just around the corner — at your house or your neighbor’s.

No responses yet