BREAKING GROUND: Teaching an old element new tricks

A CHEAPER SUBSTITUTE FOR PLATINUM A Princeton chemistry laboratory is working to make major industrial chemical reactions more efficient, less costly, and environmentally friendly. The lab has found a way to replace the precious metal platinum with iron, a much cheaper and more abundant base metal. Platinum is used as a catalyst to make a large number of products, including denim clothing, adhesives for stamps and envelopes, shampoo, herbicides, and pharmaceuticals. Platinum also is used as a catalyst in reactions that make silicones, which then are added to many consumer products (to make jeans soft, for example). The platinum adds significant cost, produces side products that require energy to separate, and leaves traces that can’t be recovered from these products.

The lab is able to replace platinum catalysis with iron catalysis by adding an organic molecule that encapsulates the smaller iron molecule, helping to drive the reaction. No added energy is needed to separate byproducts, leading to cost savings.

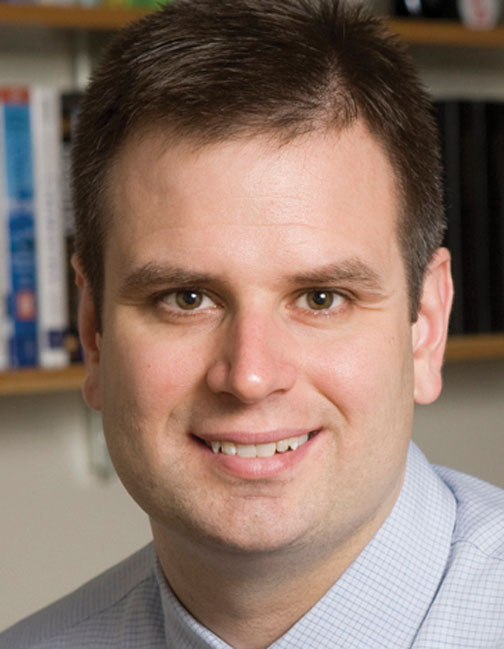

SEEKING A ‘GOLDILOCKS EFFECT’ “Working on base-metal catalysis has been a gold mine, opening a whole new reaction space for us to work, carrying out new reactions that the old catalysts could never accomplish,” said Paul Chirik, the Edward Sanford Professor of Chemistry. There still are hurdles, however. The iron compounds are effective catalysts but are unstable in air, while air-stable versions are not as effective. The lab is looking for something in between — a “Goldilocks effect,” Chirik said. The goal is to create the iron catalyst in situ so that the molecule never is exposed to air, even though the reaction can take place on the bench top and not in a purified atmosphere.

CHEMISTRY AND SUSTAINABILITY “There is a huge interest in this type of chemistry,” said Robert H. Morris, chemistry professor at the University of Toronto, who also studies iron catalysis. “It makes economic, health-related, and environmental sense to replace platinum-group metals with common metals like iron.”

Part of the draw is improving sustainability and decreasing waste. Even a small amount of waste is huge when a process is done on an enormous scale. “You need to know how every component [of a final consumer good] is made, because somewhere there is likely to be a very unsustainable process that was used to make something you think is very good for the environment. It is really important to have as little waste as possible throughout the entire pipeline,” Chirik said.

Chirik is in a good position to help end some of this waste. He is collaborating with silicone manufacturer Momentive Performance Materials and has started a collaboration with Merck Pharmaceuticals to replace precious-metal with base-metal catalysis in drug synthesis.

No responses yet