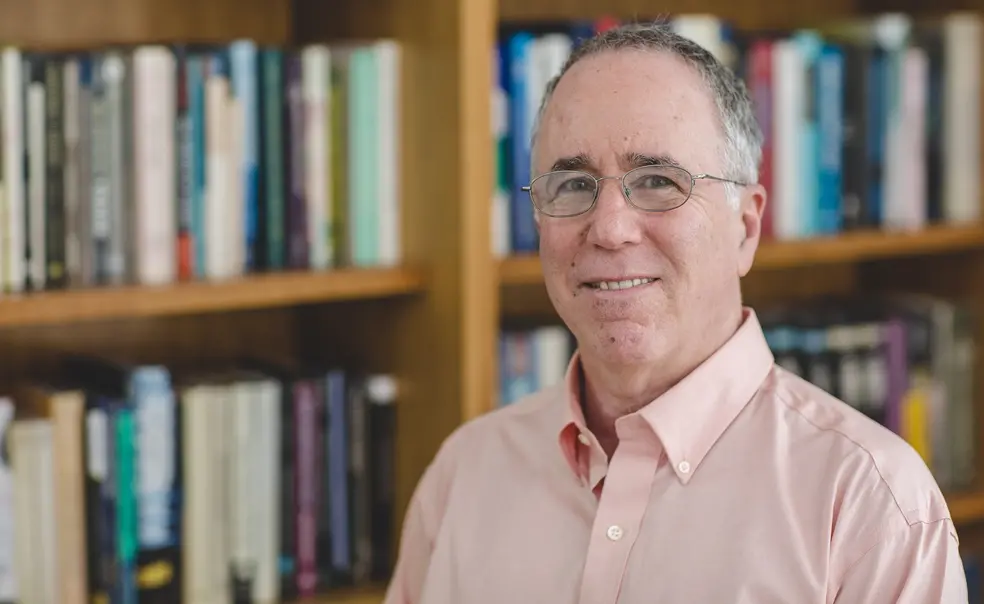

Q&A: Economist Gene Grossman Analyzes Supply Chain Challenges

‘All of these things contributed ... and it has created a big mess’

Global supply chains were thrown into chaos when the COVID-19 pandemic began disrupting life and work around the world two years ago, and we’re still feeling the effects today. We asked Gene M. Grossman, the Jacob Viner Professor of International Economics and an international trade expert, why it’s been so difficult to get a hold of everything from magazine paper — see the March editor’s note for more on how a paper shortage has had a significant impact on PAW’s page counts — to Grossman’s new dining room table, which was originally expected to arrive in June 2021 but hasn’t yet been delivered.

Why has the pandemic caused disruptions to supply chains?

Well, it has been a bit of a perfect storm. There are multiple reasons. The most direct is that different countries were affected by the pandemic at different times. Meanwhile, supply chains are “chains,” and thus only as strong as their weakest link. So, if a product passes through many stages, and one of them is disrupted because local businesses shut down, that affects other producers upstream and downstream.

The pandemic also led us to switch from consumption of services, like restaurants and travel, back toward old-fashioned goods. Demand for cars and other durable goods rose dramatically and that overloaded the ports. So, now we have ships waiting hours and days to get into the port to be unloaded. And then, in the United States, we had generous government support that led many people to withdraw from the labor force, retire early, realize they didn’t really like their job so much, together with the fact that certain jobs entailed COVID risk. So, all of these things contributed, and they all happened at about the same time, and it has created a big mess.

At the beginning of the pandemic, everyone panicked over a potential lack of toilet paper. Now we’re seeing different shortages. Is everything being affected?

Not everything, but many things. And you don’t know what’s popping up next. It’s a bit like the children’s game whack-a-mole.

Everyone was waiting for the pandemic to “end,” but now we’re learning to live with the virus. Do you see these supply chain issues ending, or will we just have to live with them?

I think we’ll return to a more normal economy. As I said, there was a perfect storm here. There’s only so many cars people can buy, and, eventually, people are going to go back to work. Or, if not them, then new workers will enter the labor force. So, I see the problems that are creating the supply chain bottlenecks easing over time.

Do you have any idea when?

I’d guess less than five years. Whether it’ll be six months or 12 months, my crystal ball’s a little cloudy.

Do you have any other predictions on what the situation will be like over the next few months?

I think we’ll see some response soon from the Federal Reserve to the rising inflation rates to take the steam out of the economy a little bit.

What long-term consequences do you see coming out of this?

I think the infrastructure in this country, especially, is sorely in need of restoration. We did pass the infrastructure bill, so I think we’ll see some attention given to improving the ports. Truck drivers were facing a bleak future even before this, due to coming of driverless trucks. To the extent that truck drivers retire as a result of the pandemic, that may be a good thing, because it will ease what was bound to be a difficult adjustment. I think we’re not going to continue to buy goods at the expense of services. When we can get back to our vacations and our restaurants, there will be some automatic correction.

How else do you see this affecting industry in the long term?

There tend to be overreactions. So, there’s a shortage of semiconductor chips today, and so the U.S. and Europe and everybody else is going to build new capacity and try to promote having enough chips for the next generation. And what we’ll end up with is too much capacity, too many chips, and then too many workers who produce chips that can’t be sold, and then we’ll have to bail them out. So, there are these cycles and overreactions. I see that as a potential long-term consequence.

For the U.S., the trend toward the service sector will continue and jobs in manufacturing are likely to continue to disappear. There will continue to be political pressures to save those manufacturing jobs, bring more of them back home, but that’s not in the cards for the U.S. Manufacturing is either going to be done in low-wage countries or it’s going to be done by robots. It’s not the future for American workers.

Sometimes we hear about issues and we picture problems across the world rather than in our own backyard.

Well, we live in an increasingly integrated global economy, so it stands to reason that wherever shocks happen elsewhere, they become our problem too. That’s the world we live in.

Interview conducted and condensed by J.B.

No responses yet